This article is based on a document in the G & T Earles archive held by the Hull History Centre - catalogue number DBEL/47/34.

In the nineteenth century, the major cement producing areas in the northeast of England, centred on the Tyne, the Wear, Hartlepool and the Humber, all used chalk shipped from the Thames and Medway as their main raw material. Chalk was used as ballast on the return legs of trips carrying heavy goods - notably coal - to London, and so was available at virtually zero cost. As the cement industry grew, producers needed to find a more secure source of raw material, and contracted with individual supplier quarries in Kent and Essex. As the commercial value of the chalk became evident, and demand grew, suppliers gradually raised prices. The growing use of iron-hulled water-ballasted coal ships further closed off the supply of ballast chalk. So an industry that initially made use of a readily available waste product ended up buying the same raw material at premium prices and paying for shipping it several hundred miles. Starting as the lowest-cost manufacturers, they ended as the highest cost.

The northeast plants became victims of circumstance partly because soft chalk from the southeast was regarded as the only raw material that could be used in Portland cement manufacture. Deposits of chalk actually extend as far north as Cleveland, but the material is much harder. As explained elsewhere, it was the slow development of grinding technology that determined the rate of innovation in the cement industry. Attempts to use the hard northern chalk using the primitive methods of grinding originally used resulted in failure because of excessive amounts of oversized (>150 μm) particles in the kiln feed, and so northern chalk got the folk reputation of being "no good". However, by the early years of the 20th century, northeastern manufacturers realised that they had to choose between innovation and oblivion.

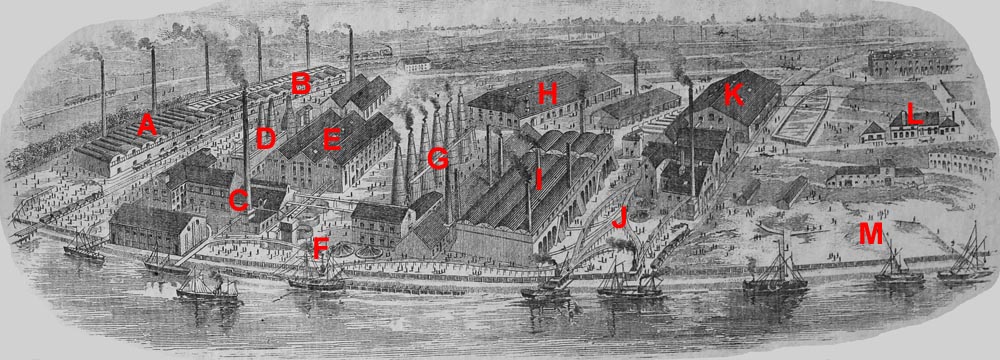

The painful process of changing raw material, which was undertaken by a few of the northern plants (the others ceased operation) is exemplified by the case of the Wilmington plant in 1902. This was the plant of G & T Earle, and in 1902 had a capacity of about 70,000 tonnes a year. It was the seventh largest in England, and the largest outside the Thames/Medway area (Note 1). After using cheap ballast for many years, the plant contracted with individual quarries for commercial chalk and in 1902 were obtaining material from Hilton Anderson & Brooks' quarry at Halling. Later, they used the Globe Whiting quarry at Greenhithe. The chalk delivered price was 6/- a ton or 9/- per ton of clinker - a little over 40% of the total manufacturing cost. For plants in the southeast, the corresponding figure was a few pence.

In 1888, its local competitor Adamant had started using chalk from across the Humber at New Cliff, Barton, Lincs. Earles had obtained an option for the use of the neighbouring Leggott's quarry, and had probably started using small quantities of the hard chalk on an experimental basis. Earle's was a family firm, with most of the equity held by members of the extended family, although of them, only John Hudson Earle, the managing director, took much interest in the business. It was clear that substantial investment at least in grinding equipment would be needed, and this came at a time when most large plants were also upgrading their kilns to modern forms. Earle had the difficult task of selling a costly project to the tight-fisted family, and asked Herbert Anderson to act as a consultant.

Herbert William Anderson (1858-1949) was the eldest son of William Curling Anderson, founder member of the Hilton Anderson partnership at Faversham, and had been the manager of the Halling Manor plant when it opened. He subsequently left the company to set up as an independent consultant. For Earle's, he produced a report with four options:

- A: supplying chalk from Barton (he calls it South Ferriby), making slurry and feeding the existing set of static kilns.

- B: supplying chalk as A, drying and grinding to raw meal, briquetting and feeding to Schneider kilns.

- C: supplying chalk and making slurry as A, and feeding to wet process rotary kilns.

- D: supplying chalk as A, drying and grinding to raw meal, and feeding to dry process rotary kilns.

He then went on to make the entirely sensible (but unacceptable) point that the cramped urban Wilmington site was not the place to make cement at all.

REPORT

of various proposals for the use of

- LOCAL CHALK -

and methods of treating it on its arrival at Wilmington at the works of

Messrs G & T Earle Ltd

by

H. W. Anderson, C.E.,

Fairfield

Teddington, London

1902

Dear Sirs,

In the portion of this report bound separately (Note 2), I treated on proposal A and under which the chalk was deposited in the storage hopper at Wilmington and used to supply the wash mills in that form instead of any London Chalk.

The next on the list of proposals enumerated on page 2 of the other report is

PROPOSAL B.

This is the same as far as delivery of the ground chalk (Note 3) into storage hopper at Wilmington, and which costs as described under A 2/- per ton of chalk.

Clay is unloaded on wharf by grab (Note 4) and fed into rotary driers by barrows from the storage heap. It is then dried and passes through a pulverizer to fine powder from which it goes into a storage hopper of about 200 tons capacity near the chalk hopper.

The apparatus at the bottom of both the chalk and clay silos and into which the material falls automatically consists of a Pratt & Whitney, or other mixing apparatus which is adjusted by the chemist as often as desirable. It is not anticipated that with the small regular percentage of moisture now left in both the chalk and the clay under this process such adjustment will be necessary as the average of both materials stored and mixed in such large bulk will run exceedingly uniform and require much less attention than in their natural state.

It will be advisable to have proving silos however, to be perfectly sure all is right in case also any error by the mixing apparatus getting out of adjustment, and to ensure the most perfect quality for the cement at all times, so from this it is conveyed in a mixing conveyor and elevator into an octagon tower as shown on drawing, each compartment is capable of storing about 150 tons of material. I may say there are a large number of works where no such precaution is taken and the mixing chamber dispensed with. This was one of the points I complained of to Edison as to his Stewartsville Works (Note 5) as all his mixing appliances were to be used before the blending of the 2 materials and not after (Note 6).

These 8 compartments would probably be occupied as follows;—

- of these would be being filled from this trough by central elevator

- being emptied to feed grit mill and thence to feed brick machines.

- being mixed off into a fourth one for correction by other central elevator.

- being filled from No 3.

- under test.

- passed ready for use.

- with neat chalk.

- with neat clay.

A mixing elevator as well as the filling elevator would be in the centre compartment of these so that anyone of them could be quickly and automatically blended with any other or corrected with a small drizzle of neat clay or neat chalk as desired by the chemist from compartments 7 and 8.

This form of construction is the simplest, compactest, and cheapest possible and is quite original and unique in design (Note 7). There are louvred openings at the bottom by which the material can be seen and poked down if it ever hangs up (Note 8) by arching over inside and no moving parts are required for closing those openings.

After leaving these chambers when approved, the material passes into large size grit mill, here it is most thoroughly further blended and incorporated and ground to the fineness desired and on leaving which it passes into a conveyor to feed the hoppers of 6 brick machines. The hourly output of these would treat material equal to about 2 cement tons perhaps, so it would be necessary to have 6 of them running night and day (Note 9).

For these a trifling percentage of water is added to that already in the material say 7% total, and compressed into bricks. These are then stacked on brick trolleys and run off to the lifts to feed the Schneider and open kilns in the condition they are and the operation is complete.

If Humber Clay has 45% of moisture (Note 10) in it to be expelled before it can be ground and 1030 tons (Note 11) of the moist clay is required weekly to produce 1600 tons of cement, this will contain 465 tons of water, and require @ 5 lbs water from 1 lb of fuel (Note 12), 93 tons of coal to dry it with 2 rotary driers running 5½ days night and day or say 130 hours apiece should just manage this quantity and so there is no margin over. It will be advisable to provide a third in case of repair stoppage, or overwork of the other 2 from damper material, but if there is always less moisture than 45%, it is probable 2 driers would be enough for the work.

The value of 93 tons of coal for three driers at say 10/- on wharf equals on 1600 tons cement say 7 pence per cement ton.

The fuel and labour credit for Motive power whether by gas engine, electric power, or steam has to be added.

This could doubtless be supplied by the wash mill engine which would not be required for its old work if this scheme of manufacture was adopted.

| Plant in connection with driers, fan, and conveyor say | 20 IHP |

| Plant in connection with pulverizer | 35 |

| Silo conveyor and mixing elevators | 10 |

| Grit Mill | 70 |

| Conveyor and brick machine. | 35 |

| Contingencies. | 20 |

| Total | 200 |

200 x 4 lbs coal per hour (Note 13) for 130 hours weekly

equals 46 tons fuel @ 10/- = £23

1 driver & 1 stoker @ £2 each night and day shifts. = £8

Oil, grease, stores &c say £2

Total £33

This equals on 1600 tons 5d per cement ton.

The Labour for all the above process may be summarised as follows:-

| 2 men wheeling in clay from wharf storage heap and feeding driers at rate of 8 tons per hour. 2 at night. 2 for day @ £2 weekly each. | £8 |

| 1 man stoking driers night and day. | £4 |

| 1 man attending motor for turning fan and seeing to material leaving the driers into hopper of the pulverizers and into which 5 tons of the dried clay would be fed hourly night and day @ £2 weekly, | £4 |

| 1 man night & day attending the mixing weighers under chalk and clay silos and conveyor and elevator therefrom to octagon tower chambers and using mixing off elevator when ordered by chemist whose orders he would be under and also attending shoots @ £2 each into grit mill. | £4 |

| 1 man attending grit mill, and feed therefrom into brick machine hopper 1 night and 1 day @ £2 | £4 |

| 1 man attending each brick machine night and day 12 men @ £2/10/- each | £30 |

| 3 lads, night and day supplying trucks to same @ £1. weekly each | £6 |

| Total | £60 |

This equals for a 1600 cement ton output say 9d per cement ton.

In actual practice of course all the above rates would be based at piecework rates, and which would run out, on average, probably slightly below above estimate (Note 14).

The labour in connection with the 17 Schneider kilns then consists of receiving the loaded brick trolleys from the lifts on upper staging. The lads attending the brick machines having put them in the lift below, 3 lads above one to each lift to run them when required and one mate to each to help unload.

| 6 lads night & day @ £1 each. | £12 |

| 3 men bringing in fuel below to lifts night & day @ £2 | £12 |

| 1 burner & mate to each pair of kilns @ £2 and 30/- each weekly, night and day = 16 sets @ 70/- | £56 |

This for 1600 ton output = 1/- per ton (Note 15).

The cost of drawing the clinker will be the same as now, probably less, as the men do not have to water the kilns at all (Note 16), and they will be nearer the clinker mills, that is 5.7 pence per ton.

FUEL With 3½ cwt coke per ton of clinker (Note 17) @ 10/- per ton = 1/9 per cement ton.

KILN REPAIRS. A charge of £10 per week for labour and material for keeping the 17 Schneider kilns in repair, or £520 per year should be enough. This is met by 1½d per ton of cement.

DRYING, MIXING AND BRICK PLANT REPAIRS. It is impossible to really say what this would run out to. If £40 weekly (equals over £2000 per year) will cover it, which it should, this will run at 6d per ton.

DEPRECIATION. If 5% over the whole Wilmington outlay including kiln plant were charged, it would be too much on some & not enough on other parts of it, but would probably form an approximate & fair amount on an average £23,500 @ 5% p.a. = £1175 equal to 3.40d per ton.

INTEREST. 5% as usual on the whole will be charged & equals same as above 3.40d per ton.

COST OF CLAY. This will be the same as incurred before in 1902. Take it at say *** (Note 18) delivered on wharf, equal to 1/4 per cement ton.

DETAILS OF ROUGH AND VERY APPROXIMATE ESTIMATE OF OUTLAY REQUIRED UNDER PROPOSAL "B".

| £ | £ | |

|---|---|---|

| Ferriby plant (as under "A") | 12,000 | 12,000 |

| Lighterage plant (optional) | 10,000 | 10,000 |

| WILMINGTON PLANT | ||

| 1 hanging discharge elevator with motor and balanced bracket arm say, | 600 | |

| 1 elevator therefrom to hopper with conveyor, | 500 | |

| Chalk storage hopper say, | 1,900 | |

| Weighing machine and shoots, | 300 | |

| 3 rotary driers and stage and fan, | 1,850 | |

| Inclined clay conveyor to ditto, | 150 | |

| 1 conveyor and 25ft elevator, | 100 | |

| 1 pulverizer and hopper over, | 600 | |

| 1 75 (ft) elevator to clay hopper (5 tons), | 100 | |

| 1 clay storage hopper, | 200 | |

| 1 weigher and shoots &c, | 200 | |

| 82 ft spiral to octagon hopper, | 150 | |

| 1 octagon hopper in cement and iron, | 1,800 | |

| 1 90 ft filling elevator 20 ton capacity, | 120 | |

| 1 90 ft mixing elevator (50 ton capacity), | 180 | |

| Conveyor to tube mill 45 ft. 12 ton, | 100 | |

| 1 large size grit mill and hopper, | 900 | |

| 45 ft elevator to brick press hoppers (12 tons), | 100 | |

| 6 Brick machines with hopper over and conveyor over, | 3,650 | |

| Iron roofing over plant, | 1,500 | 15,000 |

| Conversion of 10 open kilns to Schneiders, | 4,000 | |

| Erection of 6 new ones (Note 19) as shown, | 3,000 | |

| 2 extra lifts for bricks and fuel, | 800 | |

| Hopper stages and gangways, | 700 | 8,500 |

| 45,500 | ||

SUMMARY OF WORKING COST UNDER PROPOSAL "B".

| s | d | |

|---|---|---|

| Cost per chalk ton f.o.b. South Ferriby 16d | ||

| freightage across 6d | ||

| discharge 2d | ||

| total 24d = per cement ton, | 2 | 10 |

| Cost clay on wharf as at present (1902) say, | 1 | 4 |

| Clay drying fuel, | 0 | 7 |

| Motive power, | 0 | 5 |

| Labor up to brick stage, | 0 | 9 |

| Kiln labor, | 1 | 0 |

| Kiln fuel, | 1 | 9 |

| Kiln repairs, | 0 | 1.5 |

| Repairs to dryers, conveyors, brick machines &c, | 0 | 6 |

| Depreciation, | 0 | 3.4 |

| Interest, | 0 | 3.4 |

| Drawing kilns clinker to crushers say, | 0 | 5.7 |

| TOTAL cost of clinker delivered at crusher, | 10 | 4 |

LIST OF PLANT DISPLACED BY PROPOSAL "B"

LIST OF CEMENT KILNS AND DRYING FLOORS (Note 20)

| No. | Type | capacity (Note 21) | £ per ton | Value £ | Future Value £ | remarks |

|---|---|---|---|---|---|---|

| 1 | open (Note 22) | 60 | 8½ | 510 | 510 | Can be converted to Schneider |

| 2 | open | 60 | 9 | 540 | 480 | ditto; staging up from lifts |

| 3 | Schneider | 80 | 20 | 1600 | 1600 | (Note 23) |

| 4 | open | 60 | 9 | 540 | 540 | staging up from lift; can be converted to Schneider |

| 5 | open | 60 | 8½ | 510 | 510 | can be converted to Schneider |

| 6 | open | 60 | 8½ | 510 | 510 | ditto |

| 7 | open | 60 | 7 | 420 | 420 | stands by itself; can be converted to Schneider |

| 8 | open | 40 | 6 | 240 | 240 | 8-10a in solid block; can be converted to Schneider |

| 9 | open | 40 | 6 | 240 | 240 | can be converted to Schneider |

| 10 | open | 30 | 6 | 180 | 180 | no dome; can be converted to Schneider |

| 10a | open | 30 | 6 | 180 | 180 | ditto (Note 24) |

| 11 | Killick (Note 25) | 60 | 12 | 720 | 0 | Extra drying accommodation over pan capacity, the excess used to supply open kilns. |

| 12 | Killick | 60 | 12 | 720 | 0 | |

| 13 | Killick | 60 | 12 | 720 | 0 | |

| 14 | Killick | 60 | 12 | 720 | 0 | |

| 15 | Killick | 60 | 12 | 720 | 0 | |

| 16 | Killick | 60 | 12 | 720 | 0 | |

| 17 | Killick | 60 | 12 | 720 | 0 | |

| 18 | Killick | 60 | 12 | 720 | 0 | |

| 19 | Converted Batchelors | 27 | 16 | 432 | 0 | |

| 20 | Converted Batchelors | 27 | 16 | 432 | 0 | |

| 21 | Converted Batchelors | 27 | 16 | 432 | 0 | |

| 22 | Converted Batchelors | 27 | 16 | 432 | 0 | |

| 23 | Converted Batchelors | 27 | 16 | 432 | 0 | |

| 24 | Converted Batchelors | 27 | 16 | 432 | 0 | |

| 25 | Converted Batchelors | 27 | 16 | 432 | 0 | |

| 26 | Converted Batchelors | 27 | 16 | 432 | 0 | |

| 27 | Hilton | 27 | 16 | 432 | 0 | |

| 28 | Hilton | 27 | 16 | 432 | 0 | |

| 29 | Hilton | 27 | 16 | 432 | 0 | |

| 30 | Hilton | 27 | 16 | 432 | 0 | |

| 31 | Hilton | 27 | 16 | 432 | 0 | |

| 32 | Hilton | 27 | 16 | 432 | 0 | |

| 33 | Hilton | 27 | 16 | 432 | 0 | |

| 34 | Hilton | 27 | 16 | 432 | 0 | |

| 35 | Hilton | 27 | 16 | 432 | 0 | |

| 36 | Hilton | 27 | 16 | 432 | 0 | |

| 37 | Hilton | 27 | 16 | 432 | 0 | |

| 38 | Hilton | 27 | 16 | 432 | 0 | |

| I | Block coke ovens | 0 | 0 | 0 | ||

| II | Block coke ovens | 0 | 0 | 0 | ||

| 19,870 | 5,410 | |||||

| Neate's Wash mill, stones, harrows, mills, elevators, wheels & pumps | 700 | 100 | at old machinery value | |||

| O&G ditto | 700 | 100 | ditto | |||

| Mixing tanks & pumps | 500 | 100 | ditto | |||

| Slurry pipes all over works | 600 | 200 | ditto | |||

| Ropeway from Hiltons to Schneiders | 500 | 40 | ditto | |||

| 22,870 | 5,950 | |||||

| Less present value | 5,950 | |||||

| Value to be written off & charged to cost of Proposal "B" | 16,920 | |||||

CLINKER IS COSTING NOW ( 1902 ) NOT LESS THAN:-

| Chalk. | 9 | / | - |

| Clay (as in "B" also). | 1 | / | 4 |

| Wet mill labour. | - | / | 10 |

| Wet mill repairs. | - | / | 3 |

| Kiln and floor labour. | 2 | / | 7 |

| Kiln and drying house fuel. | 6 | / | 10.35 |

| Faggots. | - | / | 0.75 |

| Kiln repairs. | - | / | 10.9 |

| Total | 21 | / | 10 |

This is 11s 6d more than under Proposal "B", and which saves £920 weekly equal to £47,840 per annum exclusive of 5% interest already charged, or, £2525 extra with it, making £50,365 total, being

OVER 110 PER CENT ON OUTLAY

From this gigantic saving the value of the plant displaced (£16,920) can be written off the first year.

Extra to it there will be about 5 or 6 acres of factory area not required and which if sold or let could provide cash for a great part of the outlay required for the work.

PROPOSAL C.

We will now consider this suggestion in detail. The outline of the scheme is:—

The chalk is brought to the storage hopper (and clay brought as now) and both washed as far of the slurry proving tank stage as in Proposal 'A", and then fed as liquid slurry into Rotary kilns.

The cost of slurry per cement ton under scheme "A" is,-

| Chalk | 2/10 |

| Clay | 1/4 |

| Washing labour, fuel & repairs | -/9 |

| Total | 4/11 |

and to this now has to be added that for the rotary kiln to burn it.

Seven of them will, properly worked give an output of 1600 tons weekly (Note 26). At present they are far from perfect, but with intelligent management there is no doubt great improvements can be affected (sic) and yield far beyond 240 tons per week of 5½ days night and day (Note 27).

The labour may be safely taken as follows:-

- 1 man stoking and driving engine for turning kilns & grinding coal.

- 4 men Grinding the coal.

- 4 men Burner and mate (two to work two kilns each).

- 2 men Burner and mate to work the odd kiln.

- 1 man as ganger to the lot.

- 12 men per shift or 24 required for night and day work at 45/- each all round = £54 weekly and which equals 8¼d per ton for burning labour.

REPAIRS. If each kiln had £4 a week spent on it and which over a whole year would be more than enough to provide an entirely new lining for it (Note 28), this would be say £1500 for the lot, and add £500, a most liberal amount, for repair to any of the coal grinding gear and £250 more for engine or boiler providing turning power for it. Total £250, this equals 6½d per clinker ton.

KILN FUEL. If as much as 40% (Note 29) for this be consumed for burning wet slurry and including that used for power and drying the coal, and coal costs 10/- delivered on site . This will equal 4/- per clinker ton.

MILL LABOR, FUEL AND REPAIRS. Costs you now all inclusive with your present clinker say 3/4 and if it takes 20% more to grind the rotary clinker this will increase the cost under this head to 8d per ton.

OUTLAY REQUIRED.

| Ferriby plant | 12,000 |

| Wilmington plant, | 3,500 |

| Lighterage plant, | 10,000 |

| 7 Rotary kilns (Note 30), | 14,000 |

| Elevator to mill hopper, | 200 |

| Coal grinding plant, | 1,500 |

| Shed to cover same, | 2,600 |

| Motive power for all say, | 800 |

| Total | 44,500 |

DEPRECIATION. If on the whole of the kiln plant and building 10% p.a. (Note 31) is charged this means £1900 per year and equals 5½d per clinker ton.

INTEREST. 5% on same sum means 2¾d per ton on cement.

SUMMARY OF COST OF CLINKER MADE BY ROTARY KILNS FROM SLURRY

| Cost of slurry under A scheme ( all per clinker ton) | ||||||

| Chalk | 2 | / | 10 | |||

| Clay | 1 | / | 4 | |||

| Washing expenses | - | / | 9 | 4 | / | 11 |

| Rotary kiln | ||||||

| Labor | - | / | 8¼ | |||

| Repairs | / | 6½ | ||||

| Fuel | 4 | / | - | 5 | / | 2¾ |

| Mill labour fuel and repairs &c: increase over present cost | - | / | 8 | |||

| Depreciation on kiln &c plan | - | / | 5½ | |||

| Interest on Kiln outlay | - | / | 2¾ | 1 | / | 4¼ |

| Total cost delivered at mills | 11 | / | 6 | |||

Above it is shown your present cost is 21/10 for producing clinker delivered at the mill, thus showing there would be an estimated economy of 10/4 per ton which on 1600 tons output equals £825 weekly.

| equal to per year, | 42,900 |

| Less interest on value of chalk stocks, | 250 |

| Less interest on value of coke stock, | 250 |

| Interest & profit earned by lighterage, | 750 |

| Interest on Ferriby outlay, | 600 |

| Interest on Wilmington outlay, | 950 |

| The whole of the land say 9 acres containing the whole of the old kilns, coke heaps, ovens, and chalk heaps, available for letting at say £500 annum not credited to this at all. | |

| 45,700 |

PROPOSAL D.

This suggestion is the same as B where the dry powdered chalk and clay are ready for use, after which instead of feeding brick machines it goes to Rotary Kilns for calcination (Note 32).

The powdered chalk is required and stored in hopper as in the other schemes A, B & C.

The clay is unloaded at the lower jetty beneath the chalk berth and dried. In this case, it is proposed to use the waste gas from the rotary kilns to dry the clay in these driers instead of using special fuel if they are erected in the position near the Killick kilns so as to permit this to be done and by which the estimated 7d per ton for drying fuel under scheme B would be saved.

From the octagonal blending hopper the material to ensure further incorporation and to still finer grind it, it passes as in C through the largest size grit mill, from this it is conveyed direct to the small hoppers over the rotary kilns.

The Labour previous to the kiln stage may be taken as follows:—

| 2 men wheeling clay from heap on wharf & feeding driers @ rate of 8 tons per hour. 2 at night and 2 on day duty @ £2 weekly each, | 8 |

| 1 man attending drier fan from kiln gases night and day, | 4 |

| 1 man superintending regularity of feed to drier and from same to pulverizer, | 4 |

| 1 man night and day attending mixing weighers under chalk and clay silos and conveyor and elevator therefrom to octagon tower chambers and using and attending shoots to grit mill @ £2 each, | 4 |

| 1 man attending grit mill and feed therefrom, | 4 |

| Total | 24 |

This is on a 1600 ton output equals 3¾d per ton.

LABOUR on Rotary plant same as in C, which see = 8¼d per ton.

REPAIRS also, 6½d per ton.

KILN FUEL. This for dry material should undoubtedly be less by 5%, as found elsewhere, and we will take it at 35% (Note 33) with coal at 10/- per ton and equals 3/6 per cement ton.

MILL LABOUR, FUEL AND REPAIRS. Grinding the rotary clinker will be perhaps 20% harder to grind over the present cost and raise this charge at that amount = say 8d per ton.

ESTIMATE OF OUTLAY UNDER D

| Ferriby plant as in A, B or C, | 12,000 | 12,000 |

| Lighterage ditto, | 10,000 | 10,000 |

| WILMINGTON PLANT. | ||

| 1 hanging discharge elevator with motor and balanced bracket, | 600 | |

| 1 elevator therefrom to hopper, | 500 | |

| Chalk storage hopper say, | 1,900 | |

| Weighing machine and shoots, | 300 | |

| 3 rotary driers and stage & fan & kiln connections, | 2,000 | |

| Inclined clay conveyor, | 150 | |

| 1 conveyor and 25ft elevator, | 100 | |

| 1 pulverizer and hopper over, | 600 | |

| 75 (ft) elevator to clay hopper, | 100 | |

| 1 clay storage hopper, | 200 | |

| 1 weigher and shoots &c, | 200 | |

| 82 ft, spiral to octagon hopper, | 150 | |

| Octagon hopper in cement and iron, | 1,800 | |

| Mixing and filling elevators, | 300 | |

| Conveyor to grit mill, | 100 | |

| grit mill and hopper, | 900 | |

| conveyor to rotaries, | 1500 | 11,400 |

| 7 Rotary kilns, | 14,000 | |

| Conveyor to mill hopper, | 200 | |

| Coal grinding plant, | 1,500 | |

| Shed to cover kilns &c, | 2,600 | |

| Motive power for kilns | 800 | 19,100 |

| Total | 52,500 | |

DEPRECIATION. If 5% be charged on the unloading plant 11,400 @ 5% = £570 and 10% on kiln plant. 19,100 @ 10% = £1910 or £2480 altogether and which equals 7¼d per ton.

INTEREST. on the outlay of £52,500 @ 5% p.a. = £2625 and is equal to a charge of 7½d per ton.

THE SUMMARY OF WORKING COST UNDER "D" IS THEREFORE:-

| Cost of chalk | 2 | / | 10 |

| Cost of clay on wharf | 1 | / | 4 |

| Clay drying and blending | - | / | 3¾ |

| Rotary kiln labor | - | / | 8¼ |

| ditto repairs | - | / | 6½ |

| ditto fuel | 3 | / | 6 |

| Increased milling cost | - | / | 8 |

| Depreciation | - | / | 7¼ |

| Interest. | - | / | 7½ |

| Total per cement ton delivered at mill. | 11/ | / | 1¼ |

Compared with present cost for same thing of 21/10 (see above). This is 10/8¾ saved per ton, equal to £44,200 per annum on a 1600 ton output weekly.

To this has to be added:

| Less interest value on chalk stocks, | 250 |

| Interest & profit on lighterage, | 750 |

| Interest on Ferriby outlay, | 600 |

| ditto on Wilmington outlay, | 2625 |

Making a total earned, of £48,425 by the scheme in one year.

SUMMARY OF COSTS & ECONOMY GAINED.

(all based on 1600 cement ton weekly output.)

| Proposal A | Proposal B | Proposal C | Proposal D | |

|---|---|---|---|---|

| Estimated cost £ of outlay including £10,000 outlay which is optional on lighterage plant | 25,500 | 45,500 | 44,500 | 52,500 |

| Economy gained £ per annum over present cost of working | 29,375 | 47,840 | 45,700 | 48,425 |

| % of gain on outlay incurred, engineers charge & chalk contract fine not included | 117% | 110% | 102% | 92% |

| Kilns of existing plant made obsolete & not required | 0 | 16,920 | 19,870 | 22,370 |

| Acres of works not required | 2 | 5 | 9 | 10 |

CONCLUSIONS (Note 34)

After having given these 4 schemes a fair amount of thought and sketched same out on the attached tracings and estimated outlay and working costs as near as possible and on the safe side, after allowing liberally for depreciation, even if the whole result in any case were divided by 4 to allow 75% further margin for safety, the return on the outlay in either case will be so prodigious that the most apathetic of proprietors, ought to be aroused and at once be up and doing.

As any alterations at Wilmington are so painfully tedious, dilatory, and costly, I cannot really recommend much being done there, as it is certainly at the present day not the site for a cement works and I would more strongly recommend a new works be erected entirely in Lincolnshire on the site of the quarry and only a depot be kept at Hull for local trade and rail purposes in addition to one at Goole and Grimsby &c.

If your management say they must have a works at Wilmington then I suggest proposal A for a start, you doing your own lighterage by preference.

By this scheme either of the other proposals such as C or D can be then introduced without any loss of efficiency of scheme A which forms part of all the other 3. D in the most up-to-date and next to that is C, although B seems to earn the most return for the outlay, and is more cumbersome to work as it takes more room. It would however be less nuisance perhaps to the neighbourhood from smoke.

I think that a private Co, under the name of "Cement Ltd"' or "Ferriby Chalk Co", Coronet or Silex, or whatever Co, as a blind to your connection to same, get them to erect the works and start them and you do all the sales under your own name for as much as you wish to sell under the "Pelican" brand and the run on cheaper stuff invoiced from other office as if a distinct thing. You can then cater for the high class also cheaper trades, like we did with Anchor and Hilton brands. The Wilmington mass of antiquated plant can then be shut up any time and transferred to the new and main works.

There is no doubt; you can get the money and E.B. (Note 35) and many others would only be too glad to join you. Maxted could go on the Board as a blind to your own name which need not appear on the directorate.

I have prepared an outline sketch for a 2000 ton Works for Ferriby and am also preparing an approximate estimate of cost to erect it and the cost of manufacture and probable revenue, which I will send to you shortly.

The "Pelican" is a bird renowned for being sleepy and I am quite prepared after holding this report up to its eye to still see it remain standing on one leg and after shaking itself up a bit, relapse into an apathetic somnolent state, until some great eruption comes along in the shape of another works, thus robbing it of its regular amount of grub.

Then it will perhaps bestir itself, if it is not too late. However this further warning can only be thrown at it once more although the thrower is getting a bit tired of the throwing as his stones are getting a bit used up.

This stone is a bit harder than usual and he hopes it will hurt. If this allegorical cap fits, jam it well down over your ears.

Yours faithfully,

H. W. Anderson (Note 36)