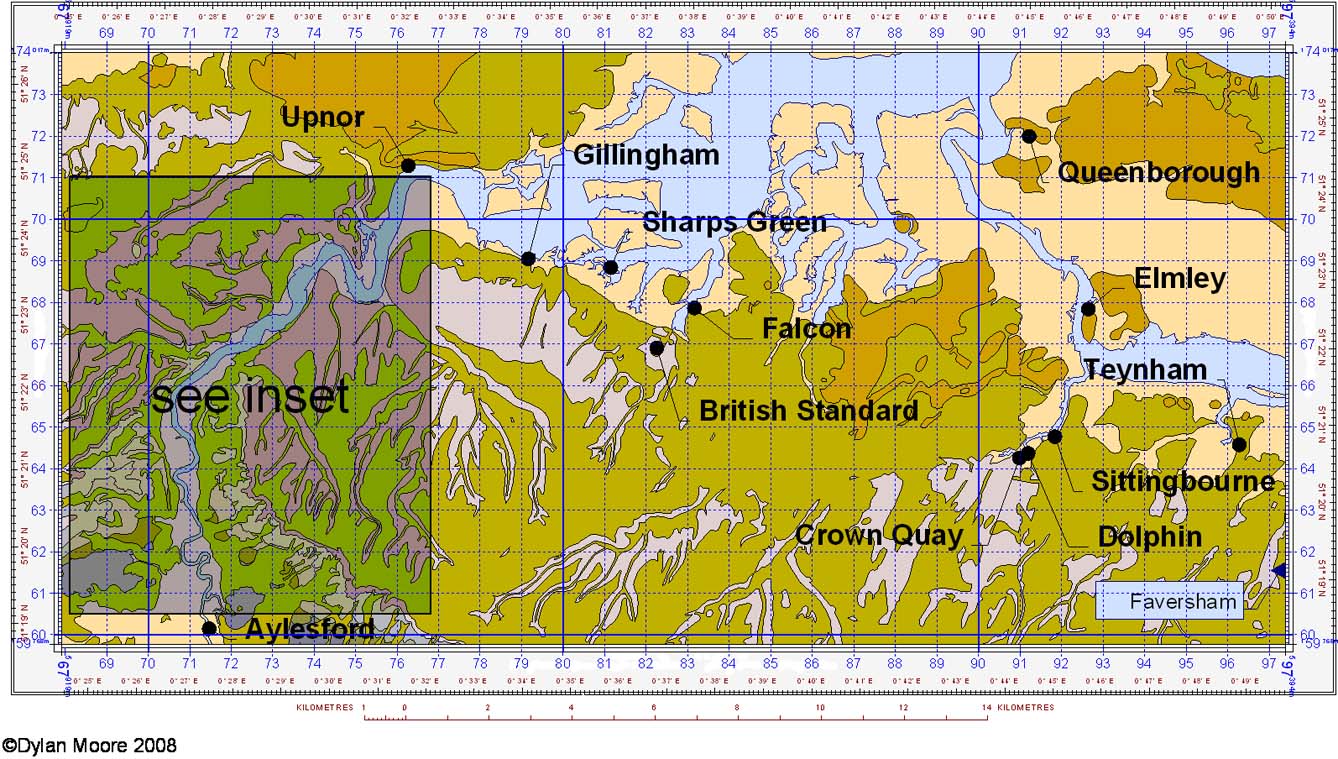

Plants on the Medway and Swale

Faversham is 4 km to the east. The plant names on this map are clickable unless your device re-sizes it.

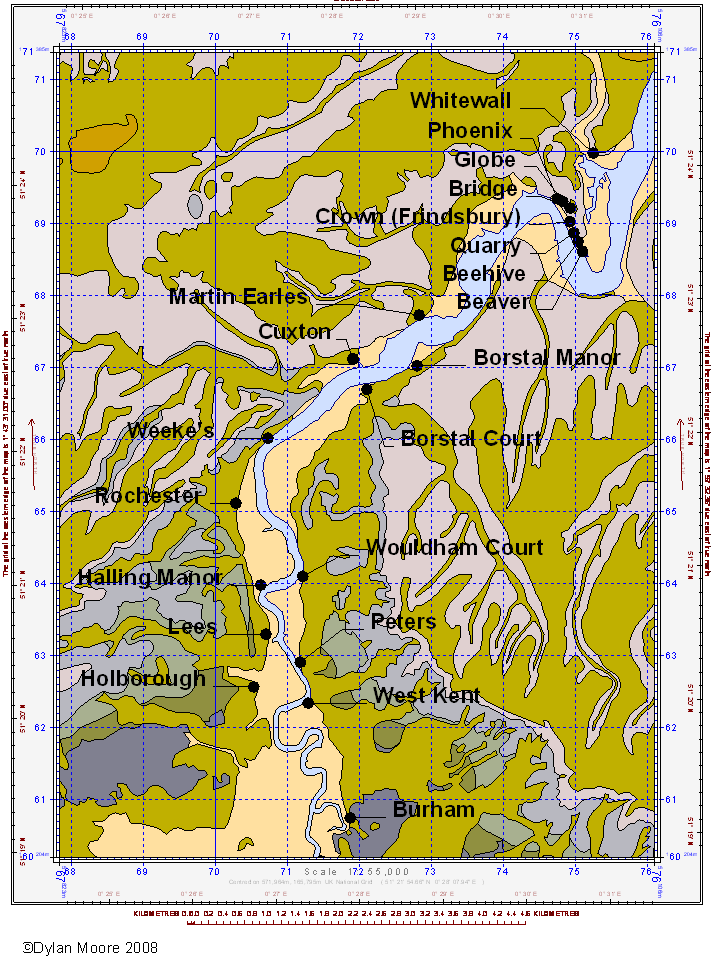

The Medway Valley, as is shown in detail in Preston's work, remained a rural backwater until the mid-nineteenth century. The Portland cement industry arrived at Frindsbury in 1851: a few years earlier, it had become an industrial centre for building materials, with establishment of plants making hydraulic building lime and bricks for the London market.

The Swale and the Isle of Sheppey had an earlier history in cement manufacture, in that they were the original source of the septaria used by Parker to make his “Roman Cement”. The septaria consisted of relatively hard nodules in the London Clay. Where the clay outcropped on the coast, low cliff sections exposed the nodules, and the beaches consisted of septarian pebbles. Parker collected these and shipped them to Northfleet for processing. Following the success of the product – and it was by far the most successful pre-Portland cement – many others secured septaria deposits and set up small plants. Many of these subsequently progressed to Portland cement manufacture.

In the Medway Estuary, the subsided remains of old meanders were exploited for clay for Portland cement. Such was the reputation of the Medway Alluvium, first used by the earliest Portland manufacturers, that it was often shipped vast distances around the coast, and even to the continent, for cement manufacture. The coastline shown in the map is roughly that of 1850: since then much of the material above high tide has been removed, and the map is now quite different.

In the Medway valley, hydraulic lime plants had used the Grey Chalk and Chalk Marl. Many of these plants converted to Portland cement manufacture, and became the first plants to use argillaceous limestone without recourse to clay addition. The main local areas with Chalk Marl are at the southern end of the Medway Gap, at the base of the North Downs scarp. Later, the Gault Clay, already much exploited for brick manufacture, started to be used as a cement mix component.

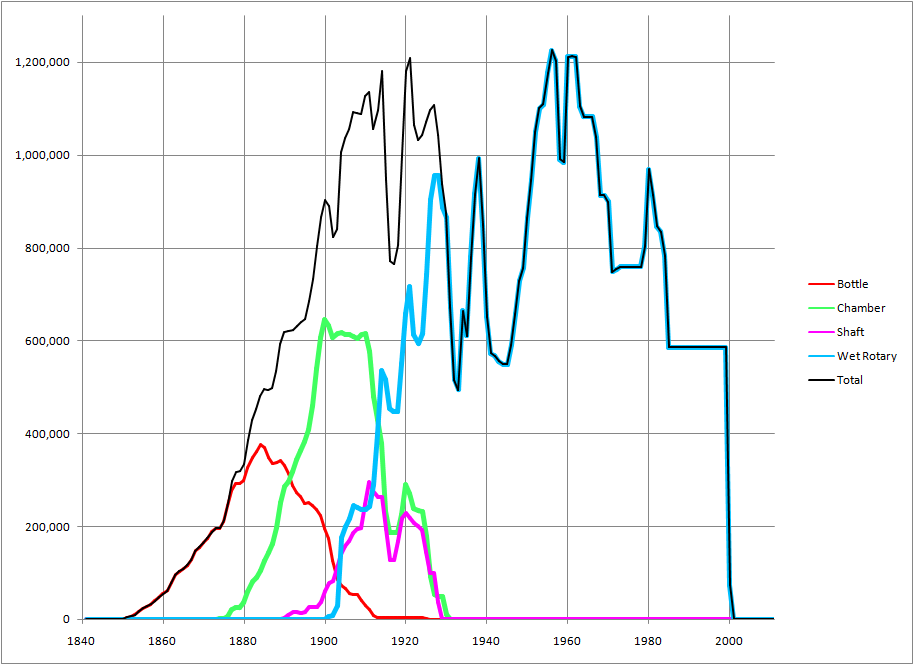

The cement industry grew up in the Medway valley dependent entirely upon barge transport for incoming materials and product distribution, and this, compared with the Thames, was distinctly inconvenient because of the low draught possible in the river and the difficulty of passing Rochester Bridge. This problem was partially alleviated by the arrival of rail on the west bank, but on the east side transport remained solely by barge until the bitter end. This is one reason why the Medway industry peaked rather early. Ultimately, as with the Thames plants, the unsuitability of the raw materials for dry processing caused the industry to wither away. Aside from the installation of kilns at Rochester, the picture was one of contraction, with Burham disappearing in 1938, Crown and Quarry, Martin Earles and Sittingbourne in 1963-1970, and Holborough in 1984. Only Rochester remained, and the industry ceased with its closure in 2000.