Richard Greaves was involved in barging between the south and north of Warwickshire, and in 1824 started making Blue Lias Lime at Wilmcote, and somewhat later at Southam. His lime was distributed as far as London through the canal system. At Stockton he set up to make "artificial cement" in 1840 by burning a mixture of ground Lias shale and burned and slaked Lias limestone. In partnership with J. W. Kirshaw, he set up at Harbury in 1858 to make Portland cement - the first in Warwickshire - by the same double burning process as used for "artificial cement". John Coulson Bull joined the partnership in the 1860s. Kirshaw retired, and on the death of Greaves in 1870, his nephew, Michael Henry Lakin joined, and the business became Greaves, Bull and Lakin. The business grew gradually, always using wet process.

The four Warwickshire companies, although all small, all invested in rotary kilns in the period before WWI: Southam in 1908, Harbury in 1909, Stockton in 1910 and Rugby in 1911. The Harbury plant grew with further kilns, and began to be upgraded when it fell within the orbit of the Red Triangle group in 1925.

An anonymous article was published in Engineering (CXXI, June 11, 1926, pp 681-685) at the instigation of Maxted & Knott, to publicise their slurry spray kiln feed system. The article is out of copyright. The slurry spray technique was tried on many cement plants, of which Harbury was probably the first, and although enthusiastically talked up at the time, it was not a success, and with the availability of chain heat exchangers and calcinators in the 1930s, all spray systems were replaced with these.

The spray process was also discussed in an article in Cement and Cement Manufacture (II, November 1929, pp 291-296), and some of this is used in the explanatory notes.

The article in passing gives a description of the plant. In the mid-1920s, it was in the same precarious state as the other Warwickshire plants - too small to be profitable, but also too small to invest in growth. The capital injection from Red Triangle gave it a degree of security, and after Red Triangle crashed in 1931, it was kept going - always on a shoestring - by Blue Circle, until 1970, when modern plant construction at Northfleet and Hope rendered it redundant.

Values of imperial units (as of 1926) used in the text (alphabetical order): 1 acre = 0.40468424 Ha: 1 ft = 0.30479947 m: 1 gallon = 4.5460756 dm3: 1 HP (horse-power) = 0.7456998 kW: 1 inch = 25.399956 mm: 1 psi (pound-force per square inch) = 6.89478 kPa: 1 ton = 1.01604684 tonne: 1 yard = 0.91439841 m.

The Cement Works of Messrs. Greaves, Bull and Lakin, Limited, Harbury, Leamington

Although Great Britain was the birthplace of the cement industry, the present annual production is only something like four million tons, as against that of the United States, which is given officially as twenty-six million tons. The rapid development of ferro-concrete in so many directions is increasing the demand for cement, and one of the most pressing needs of the industry here is the reduction of production costs to assist this country to regain its old supremacy (Note 1).

It is an axiom in the industry that the output of the kiln fixes the output of the works, and a method, such as that with which we are about to deal, by which the kiln output can be increased by something like 30 per cent. with the same fuel bill as before, merits, therefore, very close attention.

Frequently illuminating examples of progress are to be found in older establishments rather than in newly-created works, and it is easier, and often very instructive, to observe the steps by which the advance has been made. The first works in the country to adopt one of the most interesting improvements in methods of production, at all events as regards the handling of slurry, was also one of the earliest to manufacture cement.

The firm in question is that of Messrs. Greaves, Bull & Lakin, Limited, of Harbury, Leamington. This business was founded by the uncle of the present chairman (Note 2) as long ago as 1820. The works were originally engaged in burning lime, being situated on an extensive deposit of blue lies limestone and clay. These are stratified alternately in bands of from 3 in. to 2 ft. thick down a quarry face of a hundred feet or more in depth.

Figure 1: View of Original Works, circa 1840.

The image actually shows Greaves' lime works at Stockton Bridge, beside the Warwick and Napton Canal. The picture was used as a letterhead by Greaves. The Harbury plant started much later.

Aspdin patented his process of making Portland cement in the year 1824, and we understand that it was not long after that event that Mr. Richard Greaves, the founder of the firm, realising how fortunate he was in possessing both of the necessary raw materials of cement actually in the same quarry, took up its production (Note 3). Cement manufacture was certainly proceeding in the year 1847, for Major-General Sir Charles Pasley in his book on "Cement" of that date, mentioned Mr. Greave's works as being one of the three places in Great Britain at which cement was being made, and wrote appreciatively of the quality of the product. In 1855 works were built exactly on the present site, and an output of about 60 tons per week was maintained. Of the views we give, Fig. 1 shows the works some time in the early "forties": Fig. 2 is reproduced from a photograph taken about the year 1905. At the left-hand side of the later view are to be seen the drying and calcining kilns, which were, at that time, of the Johnson intermittent type. The grinding was done by means of millstones. The works as recently reconstructed are shown in Fig. 3.

Before dealing with the recent developments which form the subject of this article, the course of the materials up to the kilns may be briefly described. The clay and limestone are separated in the quarry (Note 4), and are delivered to the works in small tipping wagons which are emptied directly into the hoppers of the crushers. There are two of these for the limestone: a Hadfield gyratory machine of a capacity of 50 tons per hour, and a Goodwin-Barsby jaw crusher, of 20 tons per hour capacity. The clay, which, from the nature of its formation, is somewhat shale-like, is also passed through a jaw crusher. The broken material from the crushers is delivered directly on to bucket elevators which convey it to three storage hoppers. These hoppers are arranged in line above a belt conveyor on to which they discharge through regulating slides. The conveyor, though its primary function is that of transport, forms a mixing table for the dry raw materials, the proportions of limestone and clay being controlled by the chemist according to the results of his analysis of the slurry. The material, thus roughly mixed, is then lifted by a bucket elevator into a small hopper which delivers it onto a table feed of the circular revolving type fitted with the usual sliding collar regulator. The material is scraped off the table by a plough and falls into the inlet trunnion of a combination wet slurry tube-mill, the necessary water being added at this point. The elevator and hopper are visible in Fig. 4, which illustrates an Edgar Allen wet combination tube mill of the latest type.

This mill is 6 ft. 6 in. in diameter by 36 ft. long, and is divided into four compartments containing a total charge of about 36 tons of steel balls. It is driven by a motor of 450 brake horse-power, running at 244 r.p.m. The gearing is of the double-helical machine-cut type, and gives a reduction to the mill of about 10 to 1. The equipment also includes two ball and tube mills of the older pattern, such as are commonly used in cement works (Note 5).

The slurry discharged from the mills flows along open conduits to the storage house (Note 6). This house contains six steel storage tanks, each of a capacity of 150 tons. The slurry is delivered to the tanks from the conduits by bucket elevators, and is agitated intermittently by compressed air to prevent settlement. The outlet from the tanks is fitted with a control valve and the several pipes are coupled up to deliver into a closed conduit leading to the slurry pump. This is a belt-driven three-throw pump of the Edgar Allen type, with rams 10¾ in. in diameter. Before reaching the pump, however, the slurry passes through a centrifugal machine designed to separate out any foreign matter or unduly large particles. The pump delivers the slurry direct to the kilns, the feeding arrangements for which constitute a distinct departure from ordinary practice.

There are three rotary kilns at work, all of which are fitted with the new type of feed. These are all now about 160 ft. in length. Two of the kilns were originally shorter, but have been lengthened to the above dimension by Messrs. Edgar Allen and Co. They were originally made one by Messrs. Krupp, and one by Messrs. Newell, the diameters of shell being 7 ft. 4½ in. and 8 ft. respectively (Note 7). The third kiln is a comparatively new one, supplied by Messrs. Edgar Allen in its present form. It has a shell of 8 ft. diameter, with a burning zone of 9 ft. diameter. The kilns were lengthened before the new process was developed.

All the kilns are fitted with clinker coolers of standard type, arranged below them. The clinker is discharged, properly screened, on to a belt conveyor which delivers into a rotary clinker weigher of the spill-bucket type, of 1 cwt. capacity per bucket and fitted with an automatic counter. The rate of output is thus readily ascertained at any time (Note 8).

From a chute under the weigher, the clinker is taken direct to storage hoppers, situated over the grinding room. The conveyor used for this purpose is made reversible, so that the clinker can also be put, either wholly or partly, on a stock-heap outside the buildings. The stock-heap and elevator are visible at the left-hand side of Fig. 3.

In the process of feeding the slurry into the kilns a very considerable improvement has been made, and many of the difficulties inherent to the old system have been overcome. The new system consists of spraying the slurry into the kilns (Note 9). This process has been evolved by Mr. Thomas Rigby, M.I.Mech.E., F.C.S., the managing director of Messrs. Industrial Driers, Limited, 72, Victoria Street, S.W.1 (Note 10). This company controls all patent rights issuing licenses direct or through subsidiaries to cement manufacturers to use the process, or to engineering firms to construct the machinery. Messrs. Edgar Allen and Co., Limited, Imperial Steel Works, Sheffield, constructed the new machinery described below, and were associated with Mr. Rigby in its development, the process being known as the Rigby-Allen system. We also understand that Mr. F. S. Watt, the manager of the cement works with which we are now dealing, rendered valuable assistance in the practical application of the process.

Quite remarkable results, from a cement manufacturer's point of view, are achieved by the process, as the successful utilisation of the large amount of heat usually wasted up the chimney of a rotary kiln has effected economy in coal with a considerable increase in the clinker output. In these works, the coal consumption used to be in the neighbourhood of 32 per cent., by weight, of the clinker produced. This has been reduced to something like 24 per cent. or 25 per cent. — that is, there is saving of 25 per cent. per ton of clinker. As the kilns, however, remain suitable for burning the same amount of coal as formerly, this decrease in the fuel consumed per ton of clinker enables the clinker output to be increased without an increase in the total coal consumption. This applies to all the kilns, the increase in output being about 30 per cent. to 35 per cent. (Note 11)

As is well known, the wet process of cement-making has received most attention in this country. The undoubted advantages it possesses in facilitating correct proportioning of ingredients, their intimate mixing and control, have been recognised from an early date in the history of the industry. In other countries, however, e.g., the United States, the dry process became the recognised method, due to the obviously greater output obtainable from the same amount of fuel when fusing dry materials rather than wet ones. The wet process with the old method of slurry feed may be safely taken to give a 10 per cent. to 15 per cent. less output from the kiln than the dry process for the same fuel consumption, and, on reference to the figures given above, it will be seen that, by means of the new spray-feeding process this can be more than made good. Thus the wet process can be now made to give from 10 per cent. to 15 per cent. greater production than the dry one, while at the same time the amount of fuel required is no more than in the dry process.

This is, however, not the only advantage possessed by the spray feed. In the ordinary wet process, whatever kind of feed is employed, e.g., spoon, or tank, the slurry is introduced in a very localised manner. The resulting stream flowing slowly down the kiln, is apt to produce troublesome circular deposits, known as slurry rings, which may almost block up the kiln area. When this does not occur there is a tendency to form large balls or aggregations not favourable to the effective transfer of heat from the gases to the materials. A fall in output naturally follows such conditions. The method of introducing the slurry in a fine spray, effectually stops the formation of slurry rings. while large pieces are very rarely produced. The average size of the clinker itself is much less than with ordinary feeding methods; a handful picked at random from the stock heap will usually show about eighty per cent. of stuff about one-eighth of an inch in diameter (Note 12).

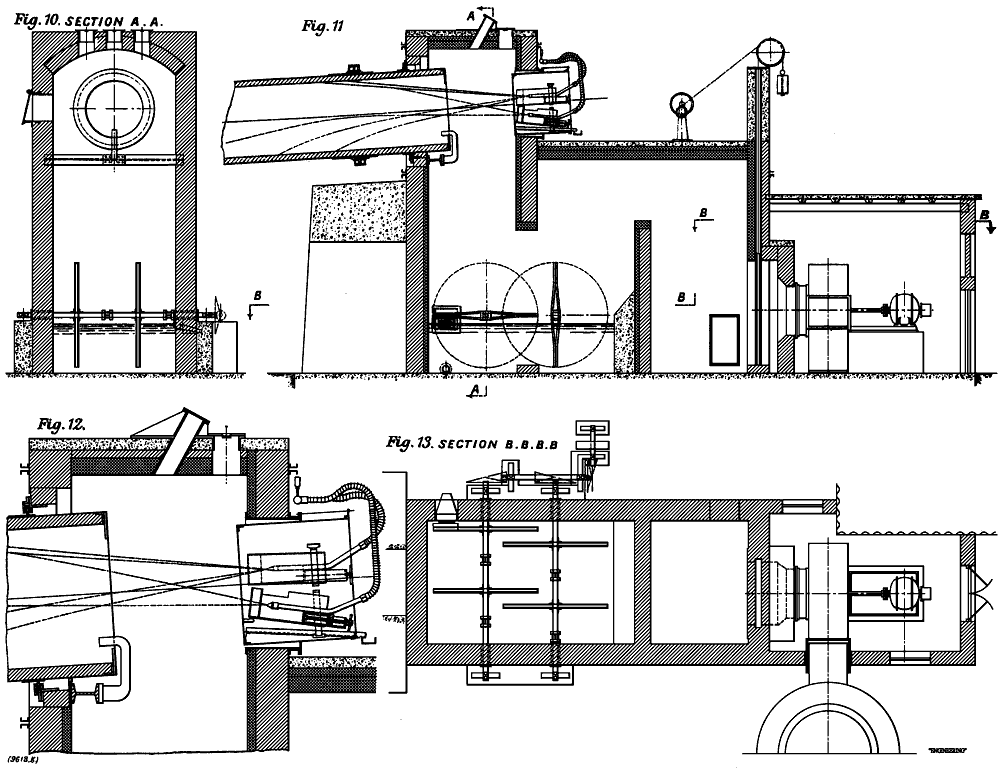

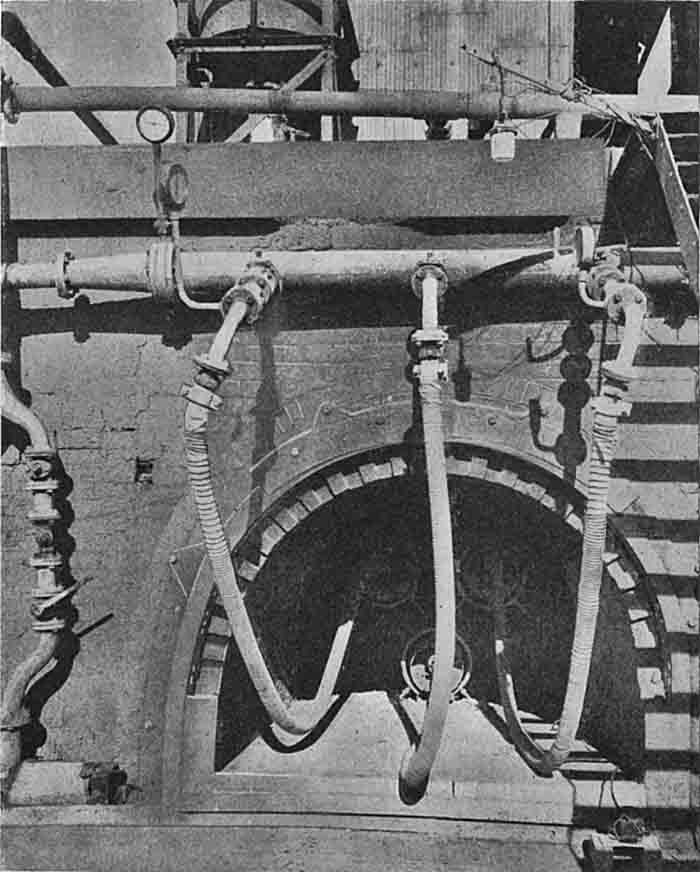

The way in which the spraying is effected is illustrated in Figs. 10 to 13. In the first place it may be explained that the existing kiln heads themselves required little alteration, the condition of the brickwork, &c., in Fig. 6, clearly indicating previous usage. A modification of the gas outlet to the chimney was, however, required, and to this reference will be made later.

As indicated in Figs. 11 and 12, the atomising of the slurry is effected by two nozzles arranged to spray into the cool end of the kiln at different angles. They are arranged with screw adjustment so that the position of the cones of spray may be altered relatively one to the other. The object of this is to obtain precise control of the cones of spray in order that they may not only fill the sectional area adequately, but may be properly distributed along the kiln. This distribution is, moreover, assisted by a difference in the atomising pressure of the two jets, one working at about 70 lb. per sq. in., the other at somewhat less. From Figs. 11 and 12 it will be seen that there is a double barrage of wide total area put across the path of the hot gases. These gases enter the atomising area at a temperature of over 600 deg. C., when slurry containing about 40 per cent. of water is being sprayed for conversion into clinker. They come into contact with a portion only of the total spray, and are partially cooled thereby, then, passing on, meet the second portion of fresh cold slurry and are further cooled. There is thus a successive " washing " and cooling of the gases which meet the spray in suspension before it falls on the kiln walls. It is found in practice that the particles of the different cones of spray, although the cones interpenetrate, have no appreciable tendency to coalesce. The higher pressure cone appears to go right through the lower pressure one and delivers at the designed zone further up the kiln. In this connection it will be realised that more spray can be dried to a given water content in the zones near the hotter gases than in those near the outlet of the kiln owing to the greater temperature difference between the gases being cooled and the slurry being dried. This is obviously greater in one zone than in the other. An important result of this method of spraying in zones, is that the gases can be cooled to very low temperatures. It is claimed that they can be taken lower than the 150 deg. C. which is normal with two zones, if more zones be used. At the time of our visit two nozzles were in operation and the pyrometer stood at about 140 deg. C.

Figure 6: Arrangement of Rigby-Allen Atomising Nozzles. These are set into the rear of the masonry kiln exhaust chamber. The original slurry feeder can be seen on the top of the chamber.

As already stated, the slurry is delivered to the atomising nozzles from the ram pumps. It passes through the upper of the two pipes visible in Figs. 6 and 7. This pipe is fitted with a relief valve, and is also connected to an automatic pressure governor seen in front of the corrugated iron shed at the end of the kiln in Fig. 6. This works automatically in the event of one of these nozzles being closed, and the surplus sherry is led back to the conduit feeding the pump. A portion of the slurry is led through the smoke chambers described later, and overflowing from there, is mixed with the raw supply feeding the pump. The connection between the nozzles and the supply pipe is made of armoured hose to allow freedom of the nozzles. These, as will be seen from Fig. 11, are outside the kiln head and separated from it by a steel plate. They are, therefore, not exposed to the hot gases, and are easily accessible for inspection, adjustment or renewal. They are of the type in which the slurry is atomised by pressure, and need no special attention, being looked after by the ordinary kiln men as part of their normal routine. The nozzles are formed with a parallel bore of small diameter at the outer or kiln end, and an inner portion which is conical and contains a separate part with spiral vanes giving "spin" to the issuing jet of spray.

The slurry is, of course, sprayed across the gap which forms the outlet passage for the gases from the kiln. This outlet is carried downwards by means of two brickwork baffles so arranged that the stream of gases flow over the surface of a considerable mass of slurry, which is kept agitated by means of paddle arms, as shown in Figs. 11 and 13 (Note 13). These arms rotate in opposite directions, and are operated by bevel-wheel gearing with a belt drive from a 6 brake horse-power motor. This gearing is clearly shown in Fig. 8. In the centre of this illustration is to be seen the motor-driven fan which exhausts the gas, and delivers them to the chimney. This fan runs at a variable speed to provide different degrees of draught, and is controlled by a rheostat arranged on the burner platform. The adoption of a fan draught, of course, renders it unnecessary to use tall chimneys, and these have now accordingly been reduced in height, as will be apparent in Fig. 3. The slurry is kept at a constant level in the slurry lute by an overflow, grid and disposed of as mentioned above. The supply pipe to the lute appears in Fig. 3. The gases from the kiln carry with them some of the dust common to all rotary kilns, and also intercept some of the spray. There results from this a semi-dry mixture which is caught in the slurry in the smoke chamber and immediately passed out for re-use mixed with the slurry (Note 14).

This contrivance practically eliminates a troublesome feature in all the usual arrangements of rotary kilns, namely, the disposal of flue dust. In the dry process about 5 per cent. in weight of the raw materials is usually carried out of the kilns with the hot gases. This has to be treated by some recovery method, but quite frequently as much as 1 per cent. gets past the most elaborate apparatus, and being ejected into the air at a considerable height by the hot gases, becomes spread over a large area. Serious trouble was experienced, as a matter of fact, in some of the fruit-growing districts of California from the deposition of dust emitted from a cement works no less than 8 miles away from the orchards. In the ordinary wet process, the difficulty persists, though it is not nearly so great. The atomising process practically cures the trouble (Note 15).

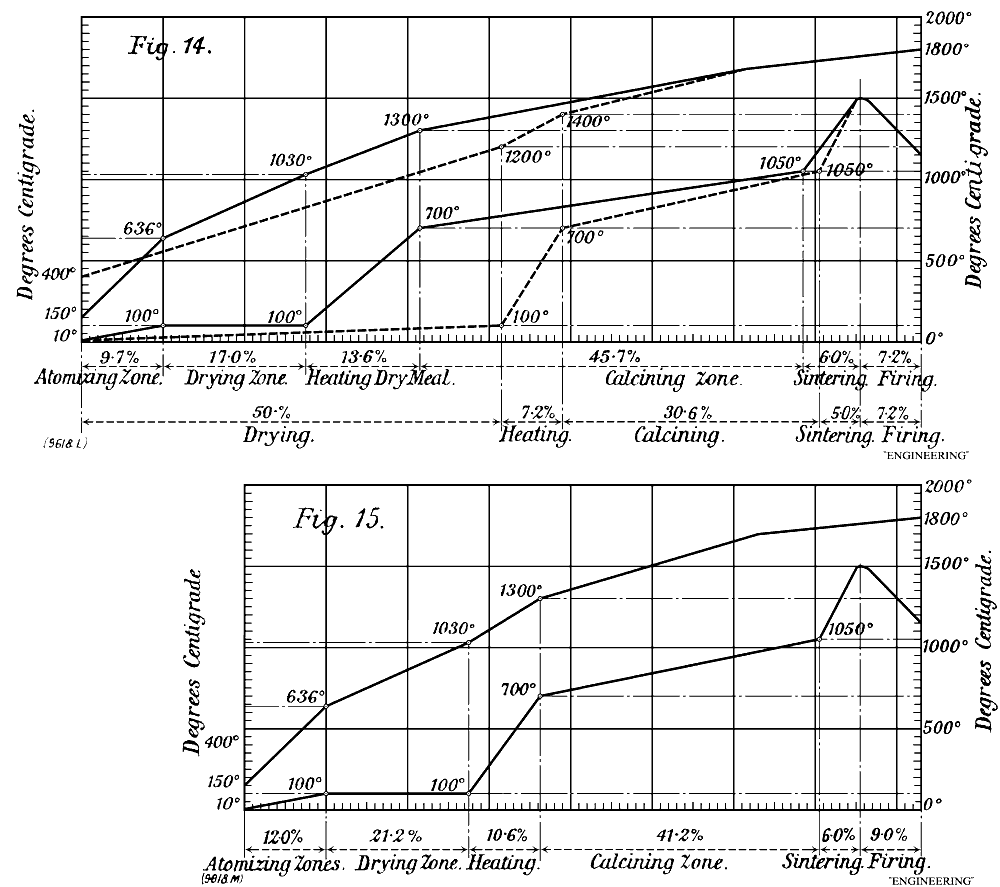

The course of the slurry through the kiln may be conveniently considered at this point and is best discussed with a reference to the temperature curves shown in Fig. 14. This figure gives two pairs of curves, the upper pair being gas temperatures, and following the path of the gas, reads from right to left. The lower pair are the slurry-clinker temperatures and read from left to right consistent with the path of the slurry. Of each pair, the dotted lines show the temperatures in a wet process kiln fed by the old method; the full lines indicate temperature for the same size of kiln with the atomizing feed. In each case the kiln is coal fired, and the maximum temperature of combustion is shown to be about 1,800 deg. C. The length of the combustion zone is, of course, the same in both cases, but beyond this the curves separate, the temperatures being given at different points to correspond with the different zones of treatment of the slurry-clinker mixture and are calculated on the known quantities of heat absorbed in raising the temperature of the material. The outlet temperature with the spray process is 150 deg. C. as against 400 deg. C. with the usual method.

Coming back from this point along the lower pair of curves it is seen that the slurry enters the kiln in both cases at the same temperature, namely 10 deg. C. With the old process, as shown by the dotted line, approximately 50 per cent. of the length of the kiln is traversed by the slurry before it is dried. When this takes place the water has been removed in the form of steam, and the time required to raise the dried slurry to the point at which decomposition of the calcium carbonate, &c., usually commences, viz., 700 deg. C., is comparatively small, only about 7 per cent. of the length of the kiln requiring to be traversed. The operation of calcining takes about 30 per cent. of the kiln length, during which the temperature of the raw material is raised to 1,050 deg. C. at which calcining is usually found to be completed. At this point the CO2 has all disappeared, and there is a marked reduction in weight of material. Thus, in practice, approximately 1.56 lb. of raw material (calculated dry), are needed to make 1 lb. of clinker, the difference representing the loss of CO2, and other gases. At 1,500 deg. C. the clinkering or sintering, is usually finished, an exothermic reaction having taken place during the fusing of the material and adding to the heat in the kiln (Note 17). The zone of maximum temperature of combustion is taken to be about 15 ft. from the firing end of the kiln, and may be considered as coincident with the maximum clinkering temperature. This point is shown on the curve as a fairly well defined peak. This, it must be admitted, is conjectural only, but it is known that the temperature of the clinker does fall again before leaving the kiln, due to the relatively cold air, required for the combustion of the fuel, passing over it.

There are two features which stand out prominently in Fig. 14. One of these is the rapid abstraction of heat from the gases, which occurs in the atomising zone, as shown by the slope of the curve of the new method, i.e., the full line. The low final temperature, viz., 150 deg. C., disposes of one problem, commonly by no means easy to solve—namely, the effective employment of the waste heat of the chimney gases. When the high temperature of the gases discharged from kilns fed in the old manner leads to the employment of a waste heat boiler in an attempt to economise, serious difficulties are apt to arise in practice from stopping the kiln temporarily, as this automatically cuts off the steam supply; other troubles are also present. Obviously with a temperature of only 150 deg. C. available, there is no necessity to fit a boiler or other means of waste heat recovery, and any steam required can be economically generated in independently fired boilers. As a matter of fact, in the plant under discussion no steam is used in the works, the whole of the machinery being electrically driven. The current is brought into the works at 12,000 volts and transformed to 433 volts A.C. for distribution.

The other outstanding feature indicated in the diagram is the greatly increased length of the calcining zone with the atomising system of feed. This follows naturally upon the decreased time required for drying the slurry, and leads to one or other of the two main advantages presented by atomising the feed. Thus, as in Messrs. Greaves, Bull and Lakin's works, with the length of the kilns unaltered, the capacity can be markedly increased. In new works, however, designed for a given capacity, the length of the kilns could be considerably shorter with the atomising process than it would be with the ordinary feed method. This not only reduces the length of the building housing the kilns, but, as they are inclined, the height of the building can be made less also. Again, difficulties in connection with the rotation of the kilns, and the power required for this are both reduced with the decrease in length. The overall effect of such a plant is to reduce the capital cost of new cement works.

An idea of the amount by which a kiln can be shortened can be given by an example. A kiln of 206 ft. long, with the ordinary method of feeding, could be reduced to 166 ft. by adopting the atomising method. Fig. 15 shows the slurry-clinker temperatures and the gas temperatures for such a short kiln for ready comparison with Fig. 14, both diagrams are made to the same scale. The two figures are aligned at the firing end, and it will be noticed that both the firing and atomising zones are the same actual length in both instances, though naturally of different proportionate length to the whole kiln.

Before leaving this part of the subject, it may be said that, owing to the absence of slurry rings, the life of the kiln lining appears to be somewhat prolonged with the new atomising feed, while the smaller size of the clinker tends to reduce grinding costs. No exact figures are, however, available in these connections (Note 18).

At the firing end of the kilns, improvements have also been introduced. The coal used is obtained from local collieries, and is of the small refuse variety, sometimes known as "duff”. It is delivered in ordinary open wagons, so that its condition on arrival varies with the weather. For example, in careful consumption tests made in July, 1925, the fuel as received contained 11.7 per cent. of water, which reduced its gross calorific value from 10,789 B.Th.U. to 9,403 B.Th.U. per lb (Note 19). The first figure is the result of a laboratory test on a dried sample; the second figure is the actual value as fired.

Formerly, the coal was dried, ground in tube mills, and blown into the kilns by a fan. The necessary plant for these operations not only took up a great deal of space but required a good deal of labour. Recently, however, all the kilns have been fitted with pulverisers of the "turbo" type. Three of these are made by Messrs. Clarke, Chapman and Co., Limited, Gateshead-on-Tyne, for Messrs. Edgar Allen, who hold the agency rights for rotary kiln installation. The fourth pulveriser is an Attritor (sic), made by Messrs. Alfred Herbert, Ltd., Coventry (Note 20). One machine of the four is generally kept idle as a stand-by.

One of Messrs. Clarke Chapman's turbo-pulverisers is shown in Fig. 5, from which it will be seen that it is a motor-driven machine of very compact design.

Wagons are run in under a bucket elevator, which lifts the coal to a storage hopper situated immediately above the turbo-pulverisers, to which it is fed without any preliminary drying or other preparation. The pipe from the storage hopper discharges into a small conical control hopper over a rotary table on the pulveriser. This rotary table regulates the feed and is driven by a belt from a small pulley on the end of the main shaft, a further reduction of speed being effected by a worm and wheel drive on the table spindle. The essential features of the pulveriser are a number of discs on the centre shaft, which carry manganese-steel beater plates, hinged on nickel-chrome steel bolts, on their peripheries. Each ring of beaters revolves in its own chamber with as little clearance as possible, the coal being passed from chamber to chamber by the action of the beaters assisted by the suction of the fan, and becoming finer in the process. The fan is carried on the same shaft and is housed in a separate casing. It has vanes of the usual spiral form. The coal is pulverised so as to pass through a 180-mesh sieve, with a normal residue, and is delivered to the kiln by the fan, through the pipe shown in the centre of Fig. 5, at a pressure of about 2 in. of water. The air inlet is by way of the vertical pipe at the feed end of the machine. This pipe is led down to the clinker coolers, drawing hot air from them. About 25 per cent. of the volume required for combustion is provided in this way. The remainder of the air from the cooler passes up the clinker chute in the firing hood of the kiln, and through the kiln to the chimney, as described above. Some cold air also finds its way in at the joints of the firing hood. The object of using heated air in the pulverisers is to obviate the use of the complicated apparatus hitherto considered necessary for drying. The turbo-pulverisers have worked very satisfactorily with coal containing as much as 15 per cent. of moisture. With cold air they are quite effective when coal of a 5 per cent. to 6 per cent. moisture content is being used.

Each machine can deal normally with about 4,000 lb. of coal per hour. They are driven by direct-coupled motors of 90 h.p., running at 1,450 r.p.m. (Note 21). As the coal is taken direct from the wagons, it is not uncommon for it to contain pieces of iron such as bolts, nuts, spikes, and so forth. These are separated automatically in the first pulverising chamber, and fall into a collecting pocket in the bedplate of the machine.

The pulverisers are under the control of the burner attendant, who is able to regulate the coal and air supply from the pulverizer, as well as the chimney draught, from the firing platform. This platform and the firing end of a kiln is shown in Fig. 9.

The rotary clinker coolers under the kilns do not call for special mention, other than at Harbury it has been found that, though the coolers were not lengthened, they are adequate to deal with the increased output. The degree of cooling is satisfactory, as is evidenced by the use of rubber conveyor belts, and the ability to cool the larger quantities now being handled is, perhaps, attributable to the smaller size of the clinker produced with the new slurry feed.

There are three cement-grinding mills in use, two of them being combination mills and the other a ball-and-tube mill (Note 5). One of the combination mills was made by Messrs. Newell. The other is of Messrs. Edgar Allen's make and is 6 ft. in diameter by 32 ft. 6 in. long inside the tube. Two slotted cast-steel diaphragms, permitting the passage of the material, divide it into three compartments. The first two of these are lined with stepped plates of chrome steel. The last, or finishing compartment, which is the longest, has a special hard cast-iron lining. All contain steel balls, the total weight being about 25 tons. Those in the first compartment are 3 in. and 4 in. in diameter, while the finishing balls are 1 in. in diameter, the middle chamber containing an intermediate size. The mill is driven by a 400-h.p. motor, running at 590 r.p.m., through a double-helical totally enclosed reduction gear, the speed of rotation being 25.3 r.p.m.

The clinker is fed from the storage hopper on to a rotary table feeder which delivers it into a feeding drum at the end of the mill. This drum contains a steel spiral partition which lifts the clinker from the periphery as it rotates, imparting in the process sufficient impetus to carry it through the hollow trunnion into the grinding chamber of the mill. Effective dust-collecting apparatus is fitted throughout.

The cement is ground to a high degree of fineness, the residue on a 180 by 180 sieve being anything between 4 per cent, to 8 per cent., with only a fractional residue on a 76 by 76 sieve. This compares very well with the new British Standard specification, 1925, which limits the residues to 10 per cent. and 1 per cent, respectively. In order to verify the claim that the quality of the cement has not been affected adversely by the new atomising process, we are able to give some test figures, by the courtesy of Mr. A. W. Ward, Borough Surveyor and Engineer, Shrewsbury, Messrs. Wm. Muirhead, Macdonald Wilson and Co. Limited, the contractors, and Messrs. David Kirkcaldy and Son. These show the results of tests of cement used in the construction of a bridge at Shrewsbury. These tests were made at Messrs. Kirkcaldy's testing and experimenting works, 99, Southwark-street, S.E., in February, 1926. The mean tensile strength of six samples of neat cement, gauged with 23 per cent. water, was 958 lb. per square inch at seven days (B.S.S. 600 lb.). Similar tensile strengths for 3 parts standard sand and 1 part cement, gauged with 8 per cent, water, gave 433 lb. per square inch at seven days (B.S.S. 325 lb.) and 519 lb. per square inch at 28 days (B.S.S. 456 lb.) (Note 22). The fineness tests showed a residue of 6.9 per cent. on the 180 sieve, and 0.2 per cent. on the 76 sieve. The initial setting time, gauged with 23 per cent. water, was 2½ hours, the cement being set hard in 3½ hours.

These figures refer to the standard cement. Two other qualities are made at Harbury, namely, a quick-hardening cement for special purposes, and a cement for use in reinforced-concrete work, having hardening properties midway between the other two. After grinding, the cement is stored in large bins which are connected at the bottom by a screw conveyor. This conveys the cement to the hoppers of the bagging machines which are of the Bates type, supplied by Messrs. Edgar Allen and Co. There are two of these, of the two-bag pattern, each capable of handling 25 tons of cement per hour, with one man per machine in attendance. The principle of this machine may be gathered from our illustration, Fig. 17. The flow of the cement into the feeding chamber is controlled positively by a rotating vane-wheel a, so that the head of cement in the chamber is approximately constant. A second vane-wheel b, running at about 1,000 r.p.m., discharges the cement through a beak-like nozzle, which is inserted into the bottom of the bag through a small hole in one corner. This hole is covered inside by a flap of material which acts as a non-return valve. The top of the bag, which is filled when upside down, rests on a cradle d the neck being previously closed by a wire wrapping and sealed. The bag is held on the nozzle, while filling, by the cam gear c. The cradle d is carried upon one end of a double-scale beam e, loaded at f, and provided with a fine adjustment at g. A sliding valve across the base of the nozzle at h, is connected at one end to a trip gear i, and at the other to a spring in tension, these details not being shown. An empty bag being slipped over the nozzle, and clamped to it, the attendant starts the feed, and the cement is rapidly discharged into the bag. When it is full, its weight depresses the cradle. This releases the trip gear, and the spring closes the nozzle valve. The bag is then pushed off the cradle by an eccentrically-operated pad j, or by a band operated device, and falls down a chute on to a truck, from which in this case it is directly loaded into the company's own wagons. The valve in the bottom of the bag is quite effective as regards prevention of leakage, and the average departure from accuracy of weighing is stated to be well within 1 per cent. of the gross weight.

Fig. 16 shows one of the machines as actually installed. It illustrates very well the scale of the plant. Two bags are seen in position, just above the platform on which the operator sits with his legs in the centre well. Below him is the chute to the loading platform. The pulley at the top of this view is that of a screw conveyor. The pulleys of the feeding vane are shown at the hopper foot, and beyond the bags may be seen the motor for driving it.

All-steel covered wagons are now used by the company, in place of the older wooden type, and a special shop is maintained to keep them in good repair.

Messrs. Greaves, Bull and Lakin have not limited their attention to the mechanical side of their business only, but devote themselves also to welfare work. A notable direction in which this has developed has taken the form of a scheme under which the firm is actively engaged in constructing houses for its employees, which, by a system of easy rental payments, will ultimately become their own property.